Products

What to do when your filter media is blinding and you can’t filter

by: Walter Senney, Lamports Filter Media, Inc. President

Many filtration applications do not require the use of a body feed or a precoat. If the solids in the feed solution are the proper size and are not “slimy” or oily, the filter media by itself will start the filtration process and the solids will build on each other. In this type of application, the media will not blind off and the proper cake thickness will result with the liquid passing through the cake until the filter cavity is packed tight. In a perfect world this would be the end of the story, but since cloth blinding does occur with little or no cake building, the use of precoat materials or media change may be necessary.

The three most common remedies for cloth blinding are a change or addition of filter media, a precoat addition to the media prior to solution feed or a body feed into the solution prior to hitting the media.

1. The simplest and least expensive remedy is to investigate the media itself.

Lab and/or pilot tests can be done to see if a tighter or looser media will help build a cake prior to blinding. The secret to filtering with just the media is to get the solids building on each other before the cloths blind.

Lab and/or pilot tests can be done to see if a tighter or looser media will help build a cake prior to blinding. The secret to filtering with just the media is to get the solids building on each other before the cloths blind.

- Sometimes a more open cloth media will allow the fine particles to pass through the media while catching the larger ones. As the media builds a cake without blinding, the smaller particles will filter out on the cake as they are recirculated back.

- Sometimes a tighter media is required to start building a cake immediately before fines can plug up the media.

- If the product to be filtered is “slimy” or oily, a “slick” cloth, like a mono/multifilament blend, may be required for less plugging and better cake release.

- Other times a paper or cellulose material may be required to be used either by itself or over a cloth media to begin the filtration process.

The goal of any of these strategies is to get the cake building, prior to any media blinding, so the solids can build on themselves.

2. The next remedy for cloth blinding is the use of a precoat material on the media prior to solution feed.

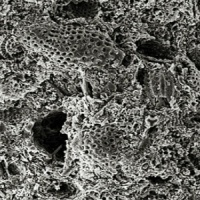

Precoat materials that are commonly used are diatomaceous earth and bleached wood pulp. These materials are mixed with water in a slurry and recirculated back through the filter until the water is clear and the media has a precoat on it. The theory is to have these porous materials set up on the media allowing solution to pass through and build a cake. The many “nooks and crannies” of the precoat give the solids places to build while still allowing solution to pass.

Precoat materials that are commonly used are diatomaceous earth and bleached wood pulp. These materials are mixed with water in a slurry and recirculated back through the filter until the water is clear and the media has a precoat on it. The theory is to have these porous materials set up on the media allowing solution to pass through and build a cake. The many “nooks and crannies” of the precoat give the solids places to build while still allowing solution to pass.

To precoat a filter some changes to the plumbing may be required as well or a tank and pump may need to be added. A rule of thumb for precoating is to use 10 pounds of material for every 100 sq. ft. of filtration area in the filter.

3. Another strategy to use that has proven very successful is the use of a body feed.

Either a diatomaceous earth or bleached wood pulp can be used here also, but the difference here is that it is mixed in with the solution downstream prior to entering the filter. This can be done by injecting it into the feed line or pre blending in the solution feed tanks. The idea is to have the body feed material become part of the product and set up on the cloth to stop it from blinding. This method has worked very well, but if the solids are your finished product, the body feed will become part of it and this may be unacceptable.

A rule of thumb here is to start with 100 pounds of body feed to 1000 gallons of solution and then wean back the amount as much as possible with each filtration cycle until the minimum amount required is used. This method may require a separate feed pump, tank and/or mixer.

Each filtration application is different and a careful study must be done to insure the correct method is used for your application. The filtration specialists at Lamports can help you solve your filtration problems and improve your efficiencies.

|

Contact us today for prices and additional information: Phone: (216) 881-2050 eMail: info@lamports.com |